Precision Plastic Injection Molding – Crafted with Care Since 2006

When quality matters most, Tennessee trusts our family.

With over four decades of industry expertise, our team delivers precision-molded plastics that exceed expectations. From prototype to production, our commitment to excellence, competitive pricing, and lightning-fast turnaround keeps your projects moving forward.

Let Us Assist with Your Plastics Projects

About Us

More Than Just Molding – We're Your Manufacturing Partners

At our Soddy Daisy facility, we're not just another injection molding company – we're your neighbors, your partners, and your advocates for manufacturing excellence. Our founders' journey in the plastics industry began in 1980, bringing over four decades of hands-on experience to every project.

Our family-owned operation has been the trusted choice for businesses across the U.S. and internationally who demand more than just parts; they demand precision, reliability, and the personal touch that only comes from working with people who genuinely care about your success.

Our story began with a simple belief: that superior craftsmanship, combined with cutting-edge technology and genuine customer service, could revolutionize how businesses think about plastic injection molding. Then in 2006, our team's decades of experience came together under the Volunteer Plastics name.

Today, with over 166 years of collective industry expertise flowing through our team, we continue to prove that family values and advanced manufacturing capabilities aren't just compatible – they're unstoppable.

Why Choose Us

The Perfect Blend of Innovation & Integrity

Unbeatable Value Engineering

Our streamlined, low-overhead operation means premium quality at prices that protect your bottom line. We leverage automation, robotic assistance, and lights-out molding capabilities to deliver efficiency savings directly to you – without compromising an ounce of quality.

Family-Owned Excellence

Every part that leaves our facility carries our family name and reputation. That means consistent quality control, personal attention to your specifications, and the kind of pride in workmanship that simply can't be outsourced or automated.

Lightning-Fast Production

Your deadlines become our deadlines. With multiple press capabilities ranging from 50 to 180 tons, plus strategic partnerships with multiple tooling manufacturers, we turn around prototypes and production runs faster than you thought possible.

Certified & Capable

From NSF-approved components for food and water applications to complex 33% glass-filled nylon parts, our capabilities span the full spectrum of injection molding challenges. If it can be molded, we've probably mastered it.

Manufacturing Capabilities

Where Technology Meets Craftsmanship

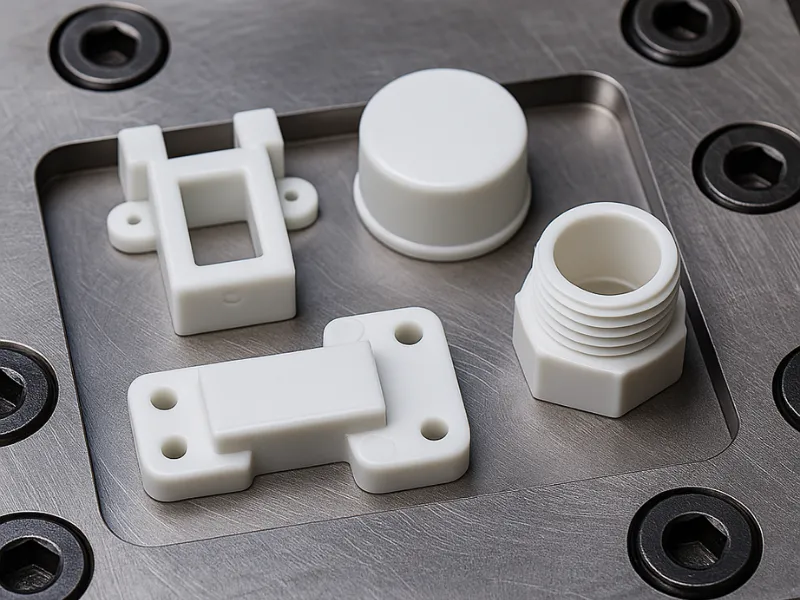

Advanced Press Fleet: Multiple injection molding presses spanning 50-180 ton capacity, equipped for everything from intricate small parts to substantial production components.

Material Mastery: Expert handling of Polypropylene, Nylon, Kevotan, glass-filled nylon, and a comprehensive range of specialized materials tailored to your application needs.

Complete Manufacturing Ecosystem: From initial prototype development and 3D modeling through full production runs, our integrated approach streamlines your entire manufacturing journey.

Quality Assurance: Every part undergoes rigorous quality control processes, ensuring consistency and reliability that meets or exceeds your specifications.

Custom Mold Development: With over 50 years of mold-building experience, our master craftsman works directly with customers to design and create custom molds that deliver exactly what you need.

WHAT DO WE OFFER?

Industries & Applications

Our manufacturing expertise spans diverse industries, delivering custom-molded solutions that power businesses across multiple sectors:

Agricultural &

Poultry Solutions

Durable components built for demanding outdoor environments and rigorous daily use.

Industrial

Components

We manufacture the hidden hero components that keep industries running smoothly.

Custom

Applications

Caps, connectors, housings, and other components designed to your exact specifications.

Whatever your industry, whatever your challenge – if it involves precision plastic molding, we have the expertise, equipment, and enthusiasm to make it happen.

Request a Quote

Ready to Start Your Project?

Ready to experience the difference that family-owned precision makes? Contact us today and discover why businesses across Tennessee and beyond choose us as their trusted injection molding partner.

📍 Visit Our Facility

8397 Gulf View Dr.

Soddy Daisy, TN 37379

📞 Speak With Our Team

— Main Office: (423) 400-5284

— Jared, Plant Manager: (423) 903-9596

📧 Send an Email to Request a Quote